Asparagus processing flowing is: Manual placement, 切断, spray cleaning and air drying, entering the visual area of the sorting machine, 並べ替え, cumulative weighing, and baling.

- Manual Placement

関数: Workers neatly place the freshly harvested asparagus on the conveyor belt, ensuring that the roots are aligned to facilitate subsequent cutting.

- Cutting

Remove the aged part of the asparagus root and maintain a uniform length (usually 18-35cm edible section is retained).

Key technologies:

The precision can reach ±1mm by using rotary blades or laser cutting machines.

Equipped with sensors to detect the diameter of asparagus and dynamically adjust the cutting position (such as cutting more thick stems and less thin stems).

Optimization suggestions:

Integrate an AI vision system to identify the quality of asparagus and classify and cut it (such as eliminating rotten stems).

- Spray Cleaning and air drying

関数: Remove surface sand, pesticide residues and microorganisms.

Process details:

High-pressure spray (water pressure 0.3-0.5MPa) in combination with food-grade disinfectants (such as sodium hypochlorite solution).

Multi-stage cleaning: Pre-rinse → ultrasonic cleaning → rinsing → air drying.

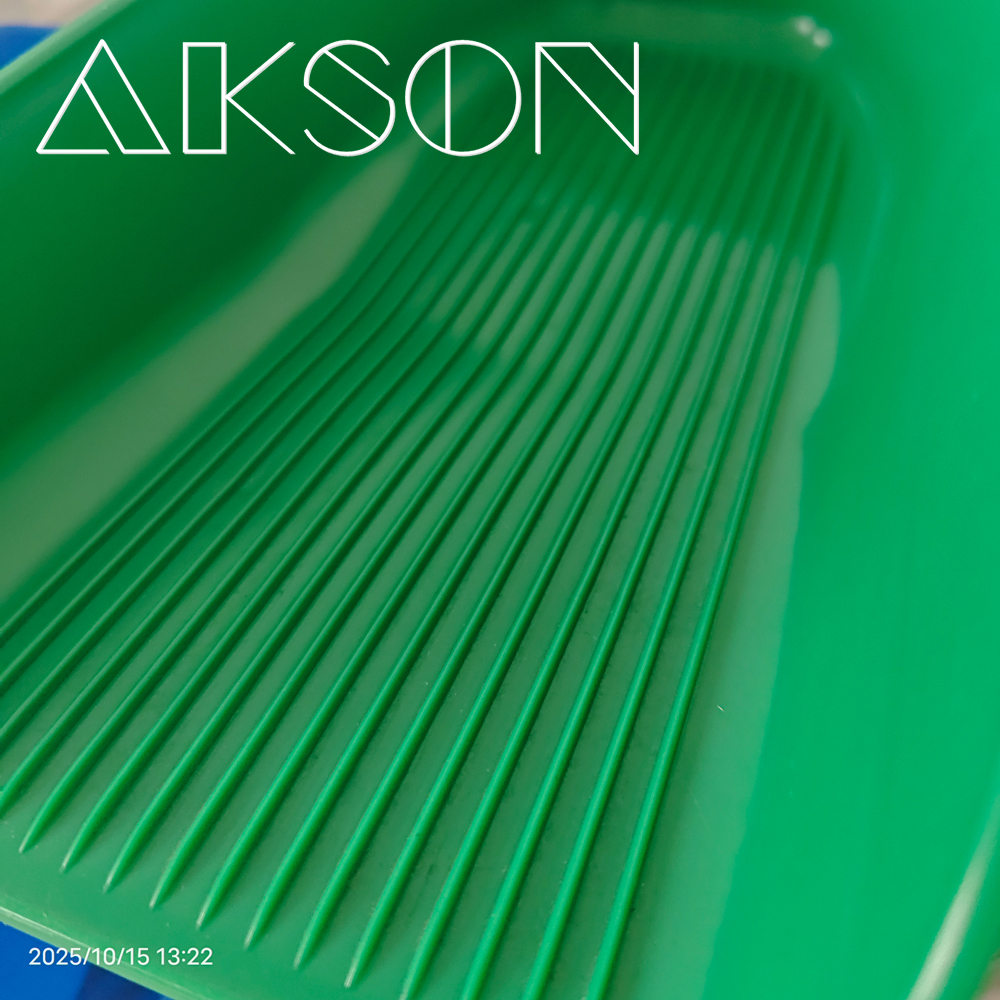

- 目視選別機

The sorting grade of asparagus is determined based on its shape, size and defects. The grade is usually determined by the outer diameter. This outer diameter can be adjusted by the touch screen.

- Cumulative weighing

The touch screen sets a weight of 500 グラム. When the asparagus reaches 500 グラム, the pneumatic door closes.

重量選別機, グレーディングマシン

重量選別機, グレーディングマシン