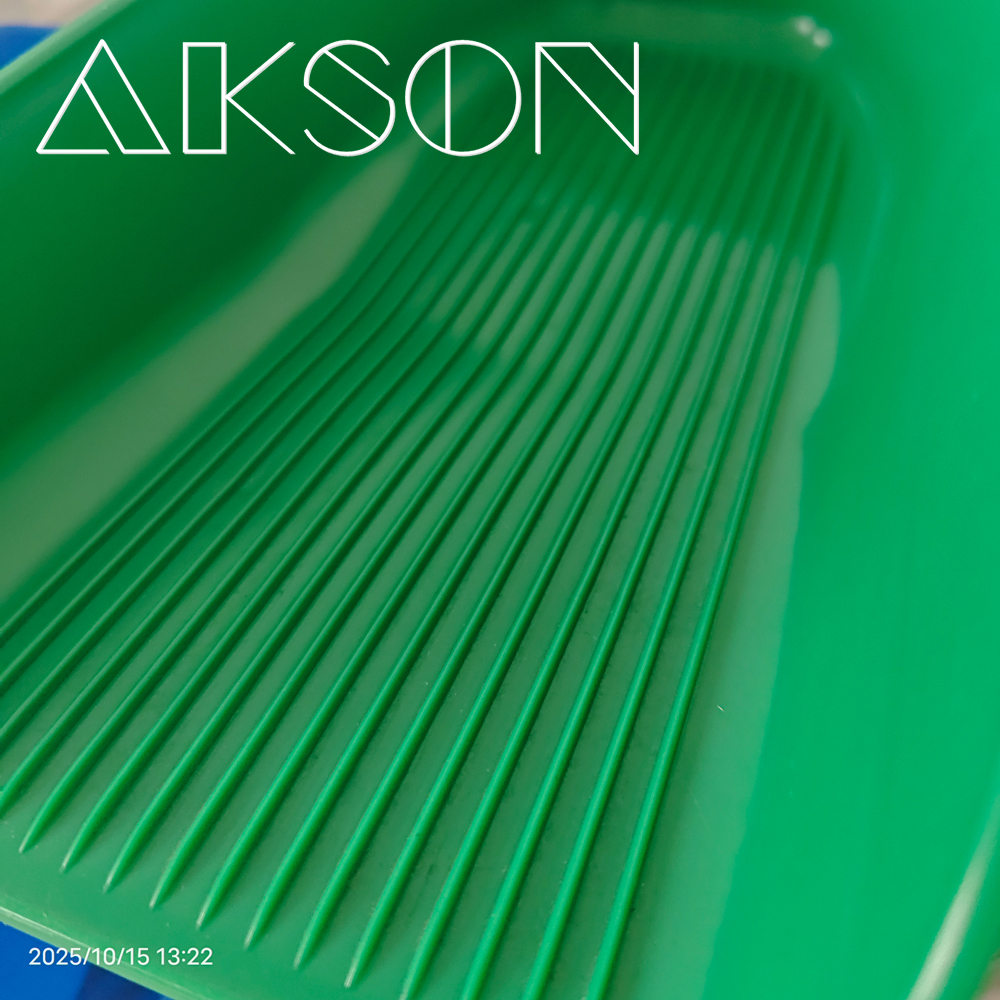

The design of the material box for the weight sorter

Specialized hoppers for weight sorting machines: Optimized for preventing sticking chicken breasts.

The core design goal of this hopper is to receive individual chicken breasts, weigh them at high speed, and then remove them to prevent them from sticking inside the hopper, ensuring absolute weight accuracy and smooth delivery of the chicken to the next process.

je. Core Feature: Surface Casting

Anti-Stick Core Mechanism:

Reducing Contact Area: Smooth surfaces create a large, close contact area with chicken, especially fresh chicken, creating a vacuum effect that causes chicken pieces to stick to the hopper and resist removal. The lattice structure divides the continuous flat surface into countless tiny raised surfaces, significantly reducing the actual contact area between the chicken pieces and the hopper, thereby fundamentally weakening adhesion.

Disrupting Surface Tension: Moisture on the surface of chicken “sticks” to smooth surfaces due to surface tension. The lattice’s concave and convex structure disrupts the continuity of the water film, preventing the water from forming a complete adsorption layer, similar to the lotus leaf effect, making it easier to separate the chicken pieces.

Liquid Diversion:

Chicken exudes water and blood during processing. The grooves between the grids create natural diversion channels, allowing these liquids to drain away quickly rather than pooling on the bottom of the chicken, forming a “water film” and further preventing sticking.

Enhancing Structural Rigidity:

From a casting perspective, grids (especially ribbed grids) are an effective structural reinforcement. They significantly increase the rigidity and impact resistance of the hopper without significantly increasing its weight or thickness, making it less susceptible to deformation during high-speed cycling and collisions, thereby extending its service life.

Providing an Anti-Slip Surface:

During the pouring process, the roughness provided by the grids prevents the chicken from sliding off prematurely. It “holds” the chicken until the hopper is tilted to a specific angle, ensuring accurate placement and preventing it from falling out of the outlet.

II. Design and Material

Material Selection:

Food-grade engineering plastics, such as PP. These materials are inherently non-stick, wear-resistant, impact-resistant, lightweight, and meet food hygiene and safety standards. Casting grids can be integrally molded.

Stainless Steel: 304 ou 316 food-grade stainless steel is commonly used. A checkered surface is created through precision casting or stamping. Stainless steel offers the advantages of extreme durability and ease of cleaning and sterilization, but it is also heavier and more expensive.

Structural Design:

Lightweight Design: While maintaining strength, the entire feed box features a thin-walled design to reduce the load on the sorting machine’s drive system, improving speed and grading accuracy.

Smooth Transitions: All corners, especially interior corners, are rounded. This prevents chicken from becoming stuck and eliminates dead corners, facilitating thorough cleaning.

Optimized Pour Spout: The pour spout is typically designed with an outward-facing or curved design, ensuring clean and efficient discharge of chicken.

Avantages: High-Precision Weighing: Eliminates weight miscalculations caused by sticking and improves product grading accuracy.

High Productivity: Ensures quick and thorough removal of chicken pieces, ensuring continuous high-speed operation of the sorting line.

Reduced Waste: Reduces the need for manual intervention and product waste due to sticking.

Easy to Clean: The lattice structure resists dirt retention, and the sleek design meets food safety requirements.

Durability: The reinforced lattice structure and high-quality materials ensure a long lifespan in harsh operating conditions.

machine de tri de poids, machine de classement

machine de tri de poids, machine de classement