Weight sorting machine and Combination Scale

1. Clasificador de peso

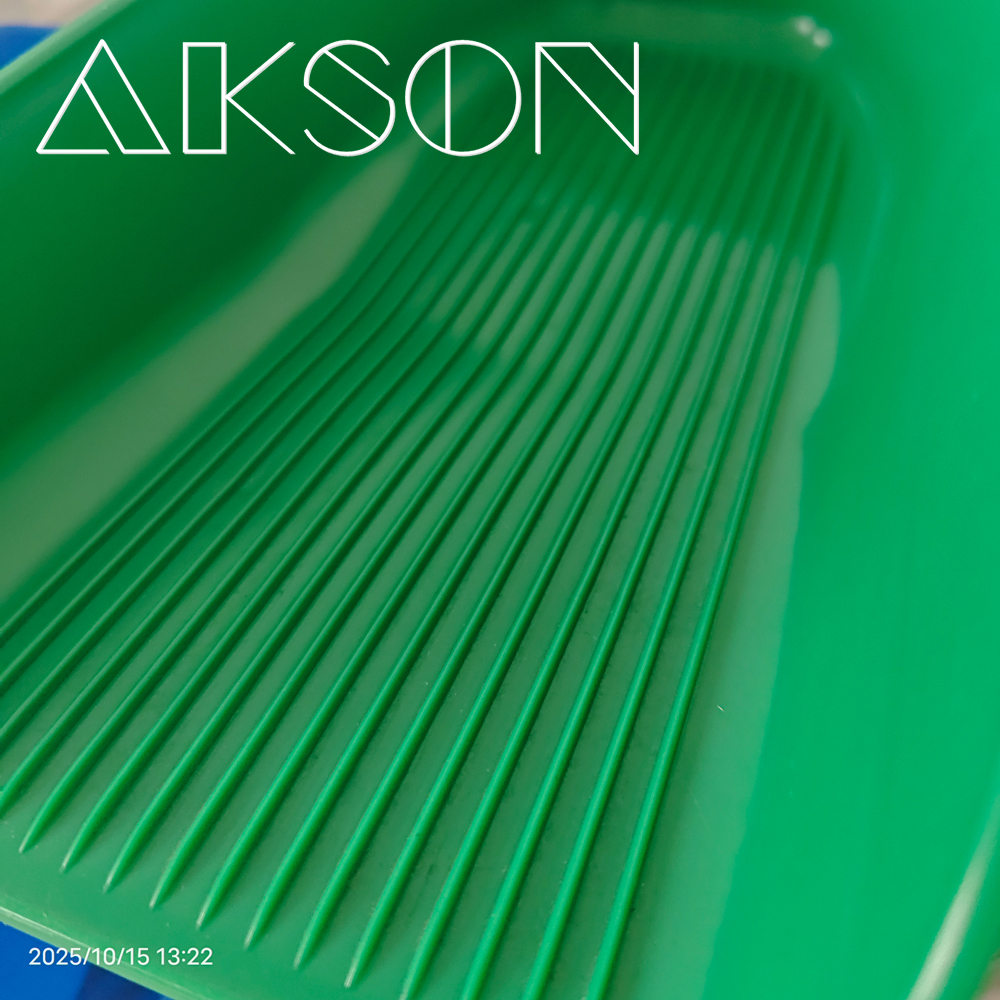

Main job: Weighs each product very accurately as it moves fast on a scale (tray-type platform). Checks and sorts products into groups based on their weight. Makes sure all finished products weigh the same, following the rules.

How it works: Products go over a very good weight sensor. The system weighs them instantly and sorts them based on the target weight.

Watching the process: Watches the product weights live on the line and sorts them.

Data recording: Records each product’s weight. Makes reports (like average weight, weight differences, pass rate) to help improve production.

2. Combination Scale

Main job: Takes products from many weighing trays. A computer quickly finds the best group of trays whose combined weight is closest to the target weight. Puts those products together.

Main use: Fast & Precise Weighing: Mainly for products that are odd-shaped or different sizes (like fish pieces, chicken chunks, wings, durian). It’s much faster than single scales for these.

Less weight waste: Finds the best combination to make the final package weight very close to the target. Saves material cost (avoids overfilling) and follows the rules.

Faster packing: Many weigh heads work together. The computer finds combinations very fast to keep up with fast packing machines.

How it works: Products go into weigh trays or onto a conveyor scale. The computer knows all tray weights instantly. It quickly finds the best group (like 3 o 4 trays together). The chosen trays open, and the products go into the bag/container. Other trays wait for the next group.

3. Combined System: Clasificador de peso + Combination Scale

Puts the Weight Sorter and Combination Scale together into one flexible machine using shared parts and smart software.

Key Shared Parts:

Shared Sorting Tray: The output of the Combination Scale (below its collection tray) connects to the Sorter’s feed conveyor. This conveyor moves the combined product and weighs it for sorting.

Shared Weight Sensor: The very good weight sensor is the heart. The system needs to make sure the sensor works well for both the Sorter and the Scale (or they might use the same sensor).

One Control System: One strong central controller (like a PLC or industrial computer) runs everything: combination finding, sorting logic, reject devices, switching modes.

Connected Data: The Scale’s controller, Sorter’s controller, main controller, and the operator screen (HMI) talk to each other instantly using fast cables. They share weight data, sorting signals, and commands.

clasificadora de peso, máquina de clasificación

clasificadora de peso, máquina de clasificación